Wings

Wings have always been a challenge to make. Julia Stoess from Insect-models.com taught us to make wings by vacuum-forming plastic. Making wings this way meant you would get a downside where the grid structure in the wing was negative and the challenge was to paint the grid structure. Even though you had a negative groove, painting this nice and tight was very hard. So we had been dreaming about taking wings to the next level. When the technology was ready, we came up with an alternative. We got a job in collaboration with Julia Stoess for Senckenberg Museum in Görlitz making a May Fly hatching from the larva. It was an impressive display where we made a 1 m. block of “water” from crystal clear epoxy with the larvae - including hairs and gills - embedded in this huge cast. On the surface of the water was a model of a May Fly. Dmytro Teslenko made beautiful sculpting - including wings. We extracted the grid structure and had it printed in SLS (Selective Laser Sintering). We also printed the entire wing print with the membrane and made a mould. After painting the grid, we placed it in the wing mould and filled it with transparent resin. This way, we made the first wings with the relief of the grid on both sides - and beautifully painted.

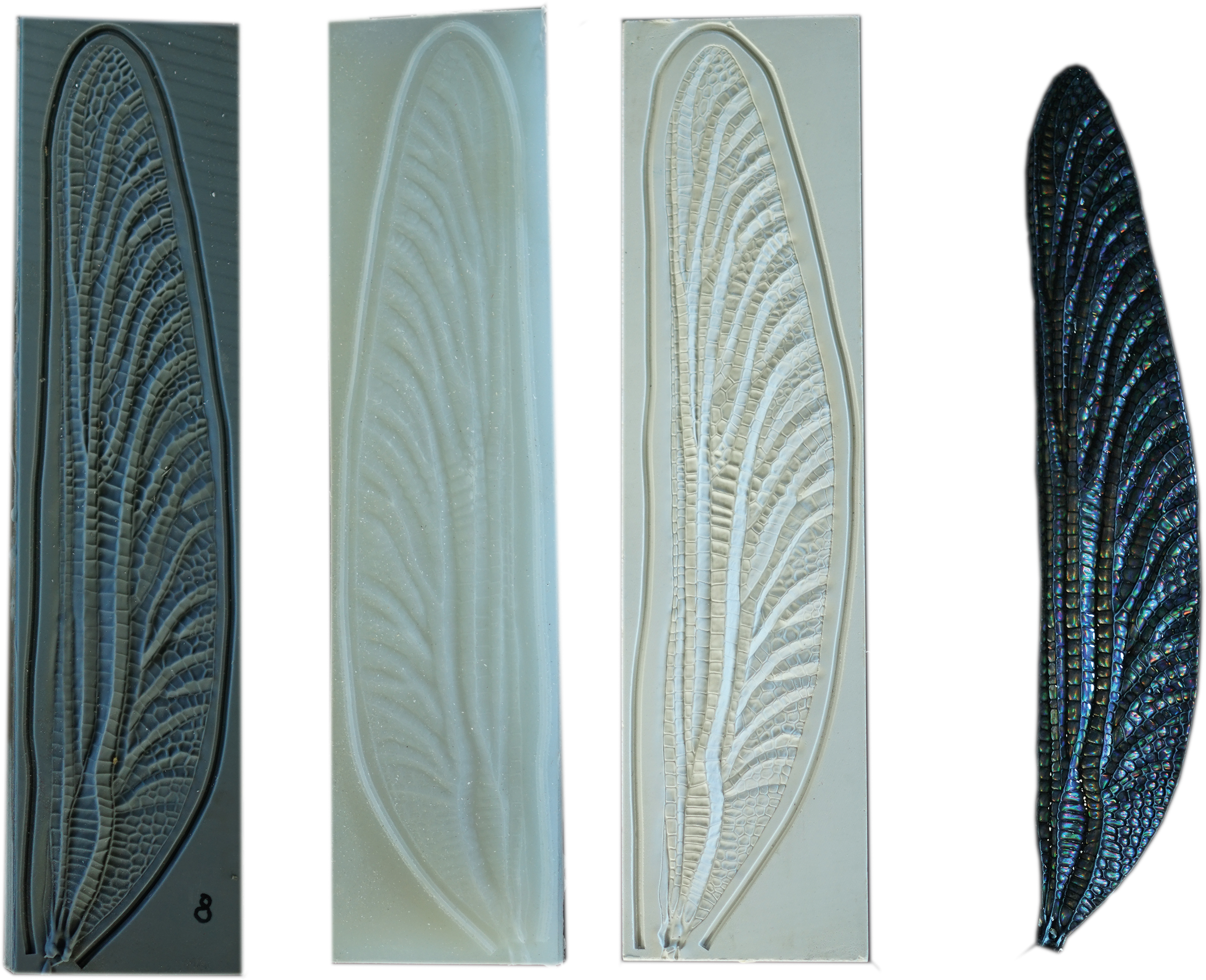

Later we got a job for the Natural History Museum in Oslo making a Meganaura - a prehistoric dragonfly. These wings were longer and slimmer, so we had problems embedding the grid structure into the wing. One of four casts came out fine, so it was hard work to make four wings for the model. When we got another request for this model, we combined the old technique with the new one. We placed the 3D printed grid structure in an open gypsum mould of the wing. Locking the grid into the vac-formed wings gave us wings with an articulated grid on both sides. Adding a lacquer on the grid site made the grid blend with the membrane so that there were virtually no differences on the two sides.